In the shotblasting process, filtration is crucial to maintain the cleanliness of the environment and ensuring the efficient operation of shot blasting machines. Filtration is used to remove dust and other waste particles from the air that are created during the shotblasting process.

In order to optimize the operation of our shot blasting machines, we have developed special PFV and PFM dust collectors that provide air flow rates from 2400 to 43000 m3/h. The dust collectors are designed according to a modern operating principle, as the air flow is directed downwards at the inlet. At the transition to the hoppers, the air velocity suddenly drops and turns upwards, allowing intensive dust extraction. Our engineers ensure the correct selection of cartridge material and fan by using special programmes to calculate losses and fan characteristics.

Dust collector cartridges

Depending on the operating conditions, dust collector cartridges made of advanced materials such as nano polyester nad nano celllose are used to ensure high operating efficiency and long service life. The twist lock fastening system enables complete sealing and efficient blowing off, as the opening of the cartridge is completely open without mounting brackets.

Regulation of operation and reduction of costs

Various options are available to make the dust collectors and the shot blasting machine work even more efficiently.

- A frequency converter for the dust collector fan enables variable fan speed and operation, thus saving on electrictiy as the flow is adjusted according to demand.

- A constant pressure gauge notifies the controller whether it is necessary to run the fan at full or reduced power.

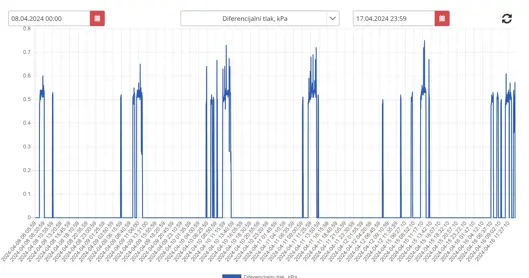

- The blow-off programmer with differential pressure gauge ensures that the dust collector cartridges are blown out only when the pressure differential between the dirty and clean parts of the dust collector rises above a certain limit. This prolongs the lifetime of the cartridges and reduces the consumption of compressed air.

Cleaner environment and lower noise

Secondary filtration provides additional air purification or prevents contamination of the air in case of damage to the dust collector cartridges. You can choose from the following options:

- A special type of cartridge that reduces dust at the dust collector outlet, which is recommended in the case of returning heated air back to the hall.

- A police dust collector prevents contamination in case of damage to the basic dust collector cartridges.

- The spatial dust collector reduces the release of particles into the environment and prevents dust from escaping into the surroundings in the event of a break in the primary filtration.

Various types of silencers can also be fitted at the fan outlet to further reduce noise, creating an even better working environment.

Comprehensive performance monitoring

Dust collector performance can also bemonitored via the Sm@rt cloud platform, which provides a comprehensive overview of parameters such as pressure differential, frequency and fan power.

For more information, contact us at marketing@gostol-tst.eu.