Shot blasting significantly improves the adhesion of paint, coating, or galvanic layers by creating a uniform rough surface that allows protective layers to bond more effectively.

At the same time, it removes rust, oils, oxides, and old coatings, ensuring long-lasting protection and a consistent surface appearance.

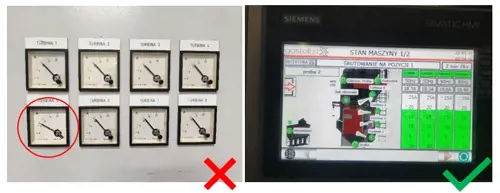

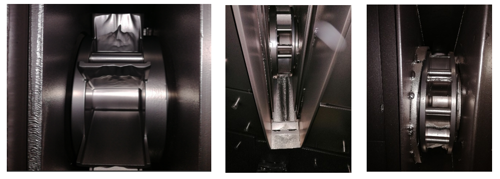

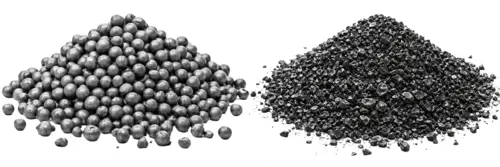

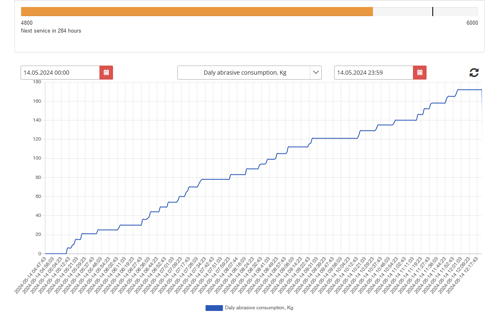

The final result depends on several factors – the type and hardness of the abrasive, the velocity of the particles, the impact density, and the degree of surface coverage. A higher impact density produces a more even roughness, which enhances coating adhesion. Other important parameters include the blasting angle, distance from the surface, and correct blasting wheel settings.

Surface quality after blasting is usually evaluated according to SA standards and the Ra roughness value, which define the level of cleanliness and the suitability of the surface for coating application.