The website uses cookies to make the website work properly and improve your experience. More information can be found in Cookie policy.

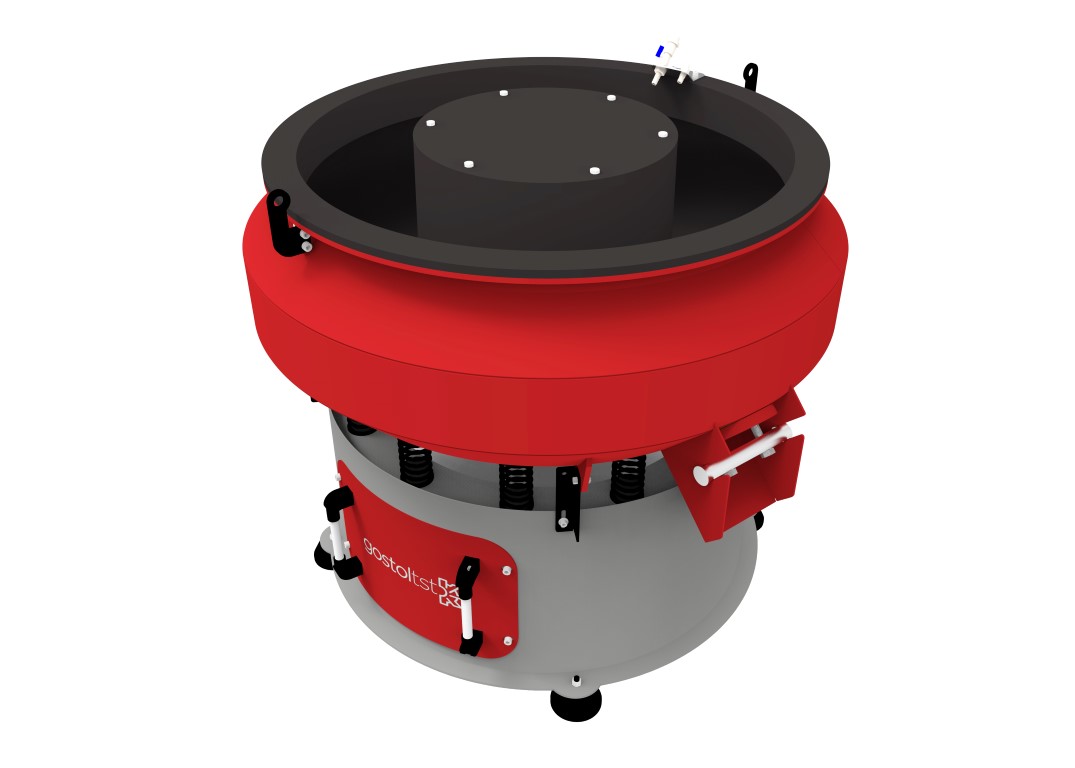

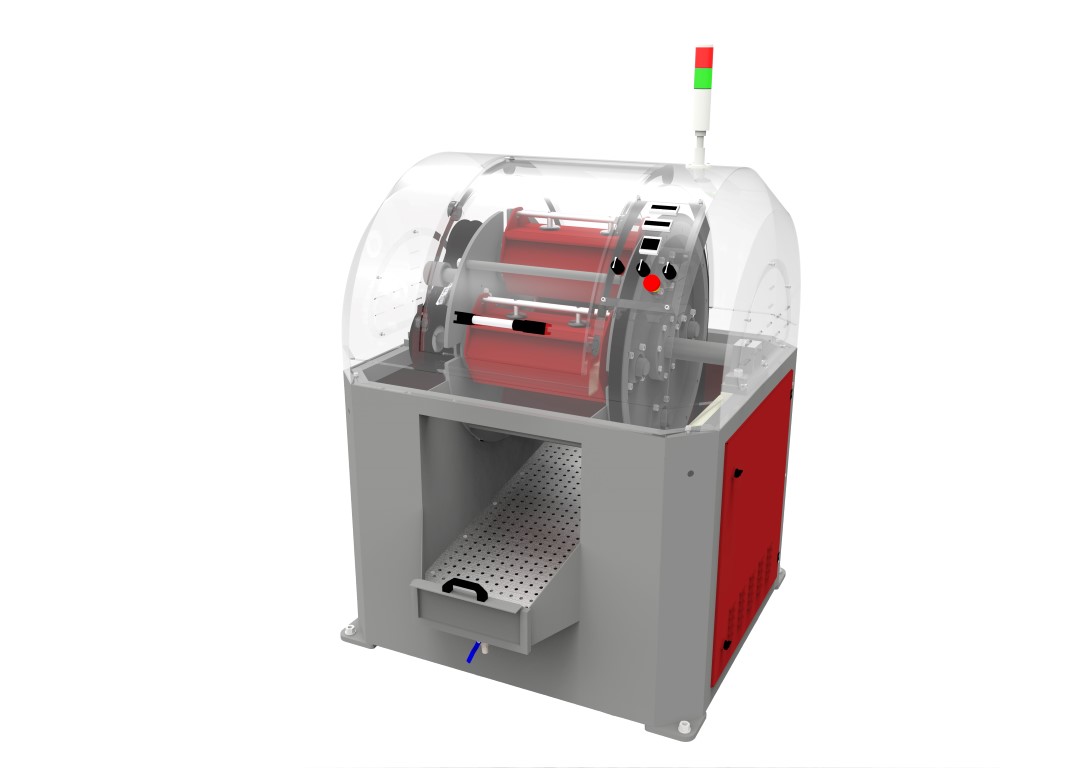

Mass Finishing Machines

Vibratory finishing is a type of mass finishing manufacturing process and can be used for cleaning, deburring and polishing products that require precise adherence to quality standards. Depending on the application this can be either a dry or wet process. At Gostol TST, we offer an extensive array of vibratory finishing machines in diverse shapes and sizes. With our wide selection, you can easily find the perfect machine that aligns with your specific needs, production capacities, and desired outcomes, be it deburring, polishing, grinding, radiusing or degreasing. Our vibratory finishing machines are designed to deliver optimal results, ensuring your products meet the highest quality standards.