The website uses cookies to make the website work properly and improve your experience. More information can be found in Cookie policy.

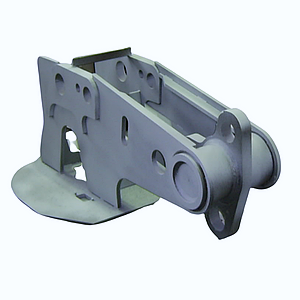

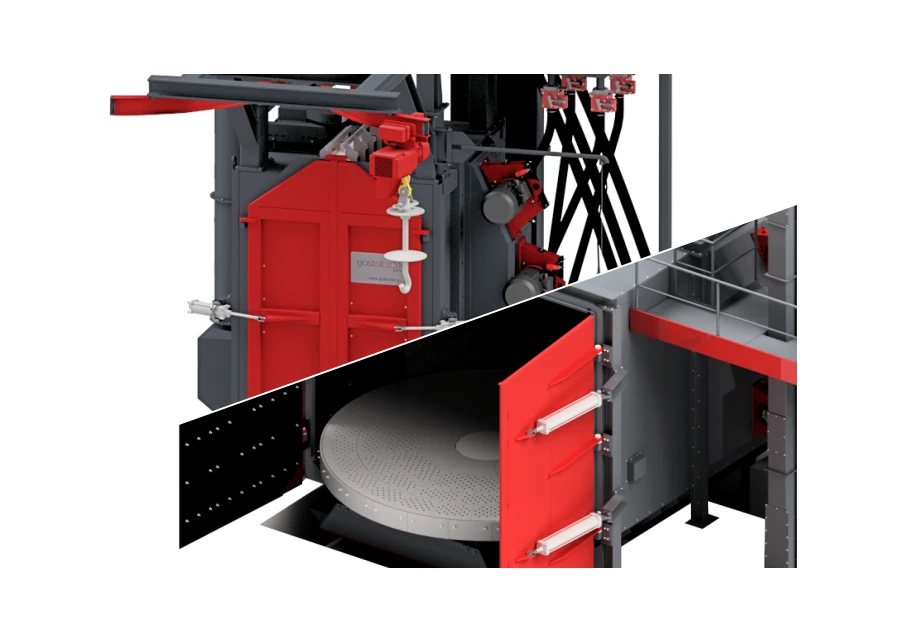

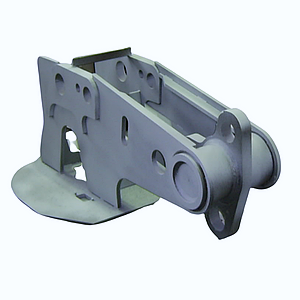

Combination of bogie table and hook shot blasting machine was designed according to specific requirements of the customer. It is used for shotblasting castings or other metal workpieces of larger dimensions and weights.

Combination of bogie table and hook shot blasting machine was designed according to specific requirements of the customer. It is used for shotblasting castings or other metal workpieces of larger dimensions and weights. Capacities depend on the selection and purpose of shotblasting workpieces weighing from 1,000 to 20,000 kg.

Shot blasting machine type KOM-VK has two ways of transporting workpieces:

The housing of the shot blasting machine is protected by wear-resistant manganese steel. The system for continuous return and cleaning of the abrasive together with efficient blasting wheels made of wear resistant materials enable high efficiency of the shot blasting machine.

We've gathered the most frequently asked questions about shot blasting machines, shot blasting process, and service and support, all in one place.

If you can't find the information you're looking for, feel free to contact us. Our team will be happy to help you to find the right solution.