The website uses cookies to make the website work properly and improve your experience. More information can be found in Cookie policy.

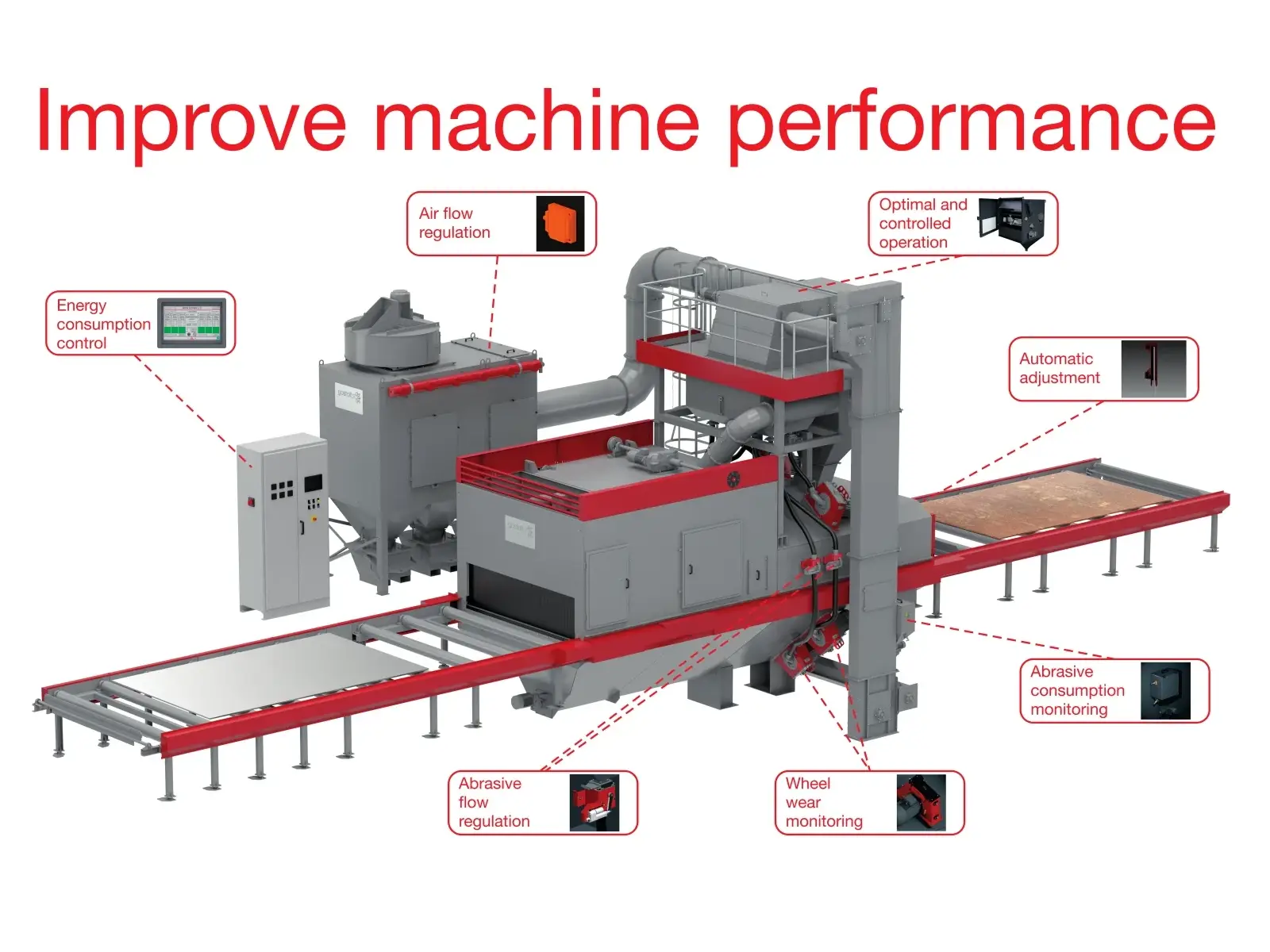

What are additional benefits of Gostol TST shot blasting machines?

Electricity consumption is proportional to the blasting time and represents somewhere between 20% and 25% of the total cost. The main elements of a shot blasting machine that affect energy consumption are the following:

In company Gostol TST, we are aware of the importance of optimizing and monitoring costs for users of shot blasting machines, which is why we offer special options (within the Sm@rt cloud platform) that enable the reduction of electricity costs.

Frequency converter for blasting wheels

It allows changing the speed and power of the blasting wheels. It is used when we have workpieces that are sensitive to deformations and to achieve better shotblasting results.

Frequency converter for dust collector fan

When full speed is not required, the fan can operate at a reduced speed, which also means less energy consumption.

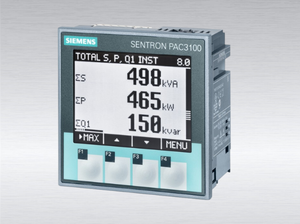

Energy measurement instrument

Monitor the cost effectiveness of the shot blasting machine via PLC.

Blow-off programmer with differential pressure gauge (Economiser)

Automatic regulation of the blowing of cartridges according to saturation.

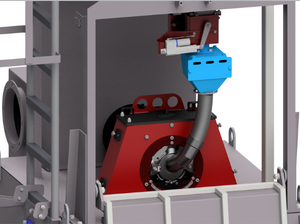

Blasting wheel door

Pneumatic closures automatically close the supply of abrasive to the blasting wheels, so the blasting wheels do not need to be stopped, which means a shorter blasting cycle time.

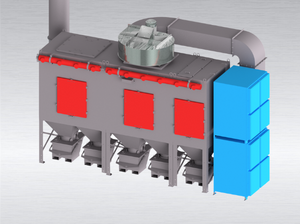

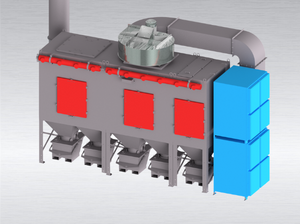

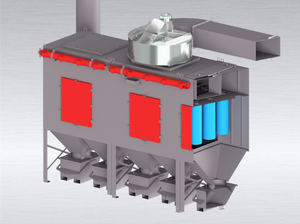

Police dust collector

It prevents contamination of the surroundings in case that dust collector cartridges are damaged.

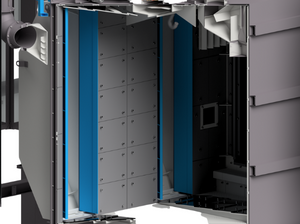

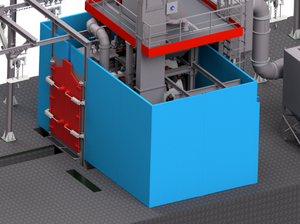

Spatial dust collector

It prevents contamination of the surroundings in case that dust collector cartridges are damaged and also reduces the release of particles into the working environment.

Blasting media consumption is a direct cost, as the number of cycles and transmitted energy of a blasting media affects consumption. It is generally estimated that blasting media represents approximately 30% of the total blasting costs.

In proportion to the smashing of the surface in the workpiece also particles of blasting media break. Estimate of blasting media wear is approx. 2 kg /h of from 1 to 3 kg per tone of cleaned castings, but it depends from case to case.

Therefore, it is very important that we do not take blasting media as a matter of course, which comes with a shot blasting machine, but we are aware of the importance of blasting media in the blasting process and we know how to make the right decisions.

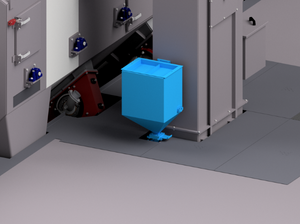

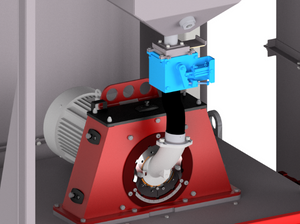

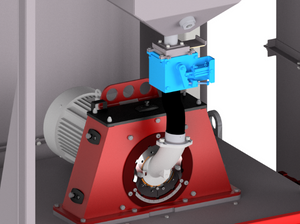

Automatic adding of abrasive

Constant and even adding of blasting media is important to achieve uniform shotblasting effect and surface quality.

Ervin abrasive

When buying a shot blasting machine, we can give you the best advice which abrasive is the most suitable for you. We recommend Ervin abrasive, which is always close to the customer.

The production process must run as smoothly as possible and without unplanned interruptions. This is often difficult to realize, but we can still do a lot on our own, as this saves money and resources.

We recommend choosing the options below, which can be installed on a blasting wheel, dust collector or shot blasting machine and will have a significant impact on lower maintenance costs.

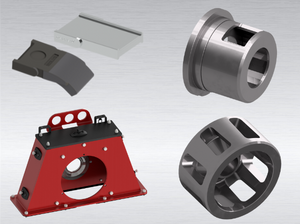

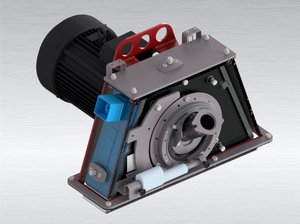

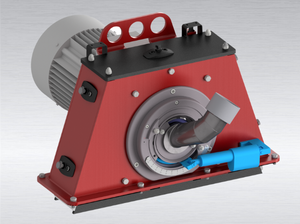

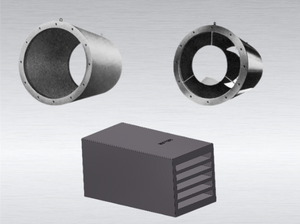

Blades, control cage, impeller and housing

For longer lifetime of blasting wheel wear parts you can choose between tool steel (2.5 times longer) or tungsten carbide (10 times longer).

Sensors system ir sm@rt

At any time you can check the lifespan of the shields, so you have immediate information about the wear of shields.

Supply filter

It protects the blasting wheel from entering of bigger parts that could damage the blasting wheel.

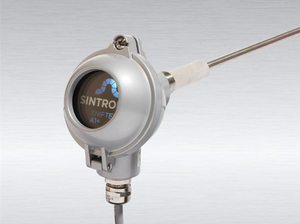

Monitor of dust for broken dust collector cartridges

It allows you to take timely action and replace the cartridge. This way you avoid exceeding the normal values.

Mechanical differential pressure gauge

The value of the pressure difference is displayed, from which the clogging of the cartridges can be determined.

Colour coating for external installation of dust collector

Better protection against rain and sun and better sealing of joints.

Network camera

Remote video and audio connection to the machine, to facilitate technical assistance for the customer.

Communication interface

A condition for the operation of the Sm@rt cloud platform, which allows full control over the operation of the machine.

Application for remote monitoring Sm@rt cloud platform

Enables you to see the status of the machine via an internet browser and to monitor current machine parameters, alarms, analytical data, etc.

To achieve optimal shotblasting results you need to keep shot blasting machine in good condition. With certain options, you can further improve its efficiency and the quality of the shotblasted surface. Some of the options are available only for some type of shot blasting machines.

Rotating control cage

Enables uniform shotblasting of different types of workpieces that are dimensionally quite different.

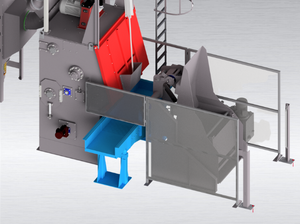

Extended trough at the outlet with screw conveyor

It enables better utilization of the abrasive, as it allows the abrasive to be returned back to the bunker.

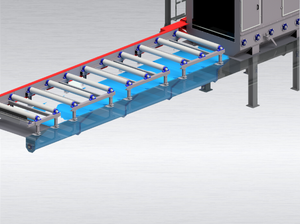

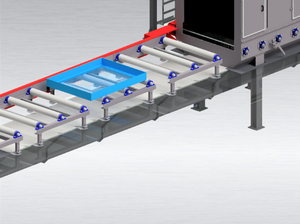

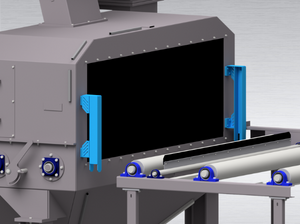

Net for blasting workpieces of smaller dimensions

This is option for roller conveyor shot blasting machine and it enables you to shotblast also smaller workpieces.

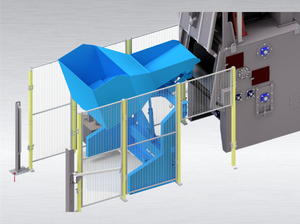

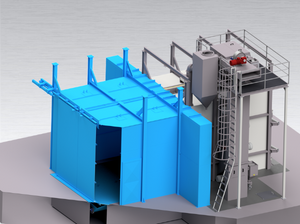

Hydraulic loader

Easier loading of workpieces into shot blasting machine.

Vibration conveyor

It is used for transport of workpieces.

Manual blowing-out chamber

This option is available only for machines type P, VKP and VPP. It is used to clean the surface of the workpieces after finished shotblasting

process.

Industrial vacuum cleaner

If you want to have clean machine environment use special industrial vacuum cleaner.

Machine noise isolation

The best choice for noise reduction.

Remote control of lifts

This option is available for machine types VK, VKP and VPP. It enables easier spatial operation with lifts.

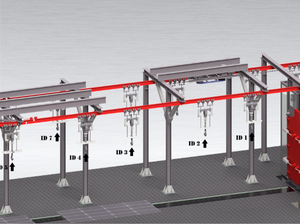

Tracking products along the line

Tracking allows the program to know exactly where a particular product is located on the line. The line thus can work with several recipes at the same time. Without this option only one recipe can be active. Available only for VKP and VPP machine types.

Reduction of dust at the outlet of dust collector

It is recommended when returning heated air back into work premises. Dust on the outlet is max. 2 mg/m3.

Fan silencer - different versions

It is mounted on the fan exit and lowers the noise. There are three different versions available.

Constant pressure gauge

Provides constant pressure in the system. This option is available only in case of installation frequency converter for dust collector fan.

Automatic heigh adjustment of brush and blow off

The brush and blow off adjusts to the workpiece, so you can blast different types of workpieces without worry about the abrasive leaking.

Semi-automatic blasting media flow adjustment

You don’t need to regulate the blasting media flow manually directly on the valve, but you can do it via switches on the electrical cabinet.

Automatic blasting media flow adjustment

This enables precise flow adjustment when required with low response time.

Application for remote monitoring Sm@rt cloud platform

Enables you to see the status of the machine via an internet browser and to monitor current machine parameters, alarms, analytical data, etc.

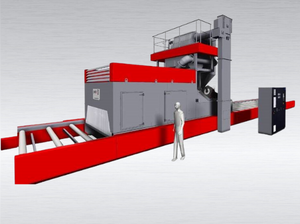

Because we know that not only the functionality of the machine is important, but also its appearance, we have prepared a set of options that will improve the design of the machine.

Painting of the equipment on request

If you want the shot blasting machine to be in line with overall graphic image of your company than this is the perfect option for you.

Decorative covers

For P machine type you can choose decorative covers along the roller, machine and cross the machine.