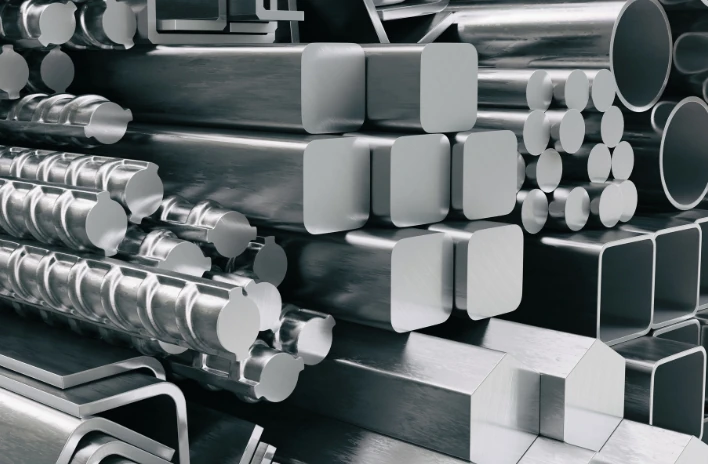

Aluminium alloy products are popular for their lightness, strength and corrosion resistance. Composed of aluminium and other elements such as copper, magnesium and silicon, these alloys offer excellent mechanical properties and good thermal and electrical conductivity. Due to the natural oxide layer, they are highly resistant to environmental influences, which makes them ideal for use in the automotive, aviation, construction, marine, sports and electrical industries. In addition, the are highly machinable, which allows for easy design and use in various production processes.

The importance of safety measures when shotblasting aluminium

The following instructions must be followed:

- Workpiece preparation: It is necessary to remove dirt, oils and other impurities.

- Shot blasting equipment: Both the machine and the dust collector must be manufactured in accordance with Atex directives. Correct machine settings and selection of the right size and type of abrasive are important.

- Workpieces: After shotblasting, the workpiece must be clean so that there is no excess abrasive, dust and other possible impurities on it.

- Equipment maintenance: The shot blasting machine must be properly maintained. This includes cleaning and maintaining the dust collector and cleaning dust from the machine and piping. It is also necessary to prevent contact of water with aluminium dust.

- Training employees on safety measures, which reduces the risk of accidents and improves the quality of work.

Safety when shotblasting aluminium products is crucial for several reasons:

- Dust exposure: Shotblasting aluminium creates fine dust that can cause respiratory problems if inhaled. Therefore, the use of a suitable dust collector is essential.

- Explosivity of aluminium dust: Aluminium dust can be highly flammable and explosive when mixed with air in certain concentrations. Therefore, effective dust removal is very important.

- Formation of hydrogen: When aluminium comes into contact with water, hydrogen is formed, which is a highly explosive gas. Hydrogen is flammable in a very wide range of concentrations, which is particularly dangerous.

What happens if safety measures are not observed?

We learned about the case of a company where all safety measures were not taken into account. The shot blasting machine was not regularly maintained, which resulted in the release of abrasive into the work area. During the shotblasting of aluminium products, a lot of aluminium dust accumulated in the room due to the poor performance of the dust collector. Employees inhaled aluminium dust, causing serious respiratory problems. In addition, due to the high concentration of the dust in the air, ignition occurred, which led to an explosion.

The consequences were as follows:

- Medical issues: Workers suffered respiratory injuries that required emergency medical attention and long-term treatment.

- Material damage: The explosion damaged equipment and the workshop, resulting in a huge financial loss.

- Business interruption: Due to the accident, the workshop was temporarily closed, which affected the production and delivery of products.

Due to the great danger present in the shotblasting of aluminium products, it is important to observe safety measures and choose a qualified manufacturer of shot blasting equipment, as only this can provide high-quality equipment that is designed and manufactured in accordance with Atex directives.

For more information, contact us at marketing@gostol-tst.eu.