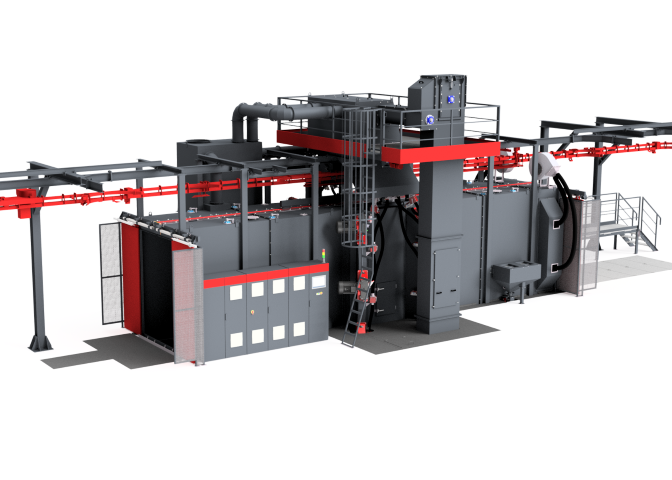

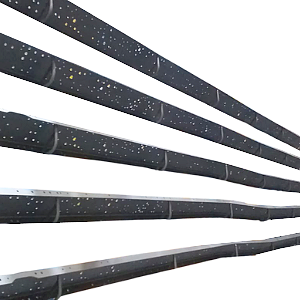

Pass-through monorail shot blasting machine is designed to process long, tall and narrow weldments without a flat surface, weighing from 25 to 1,000 kg or more and made in small or medium-sized series.

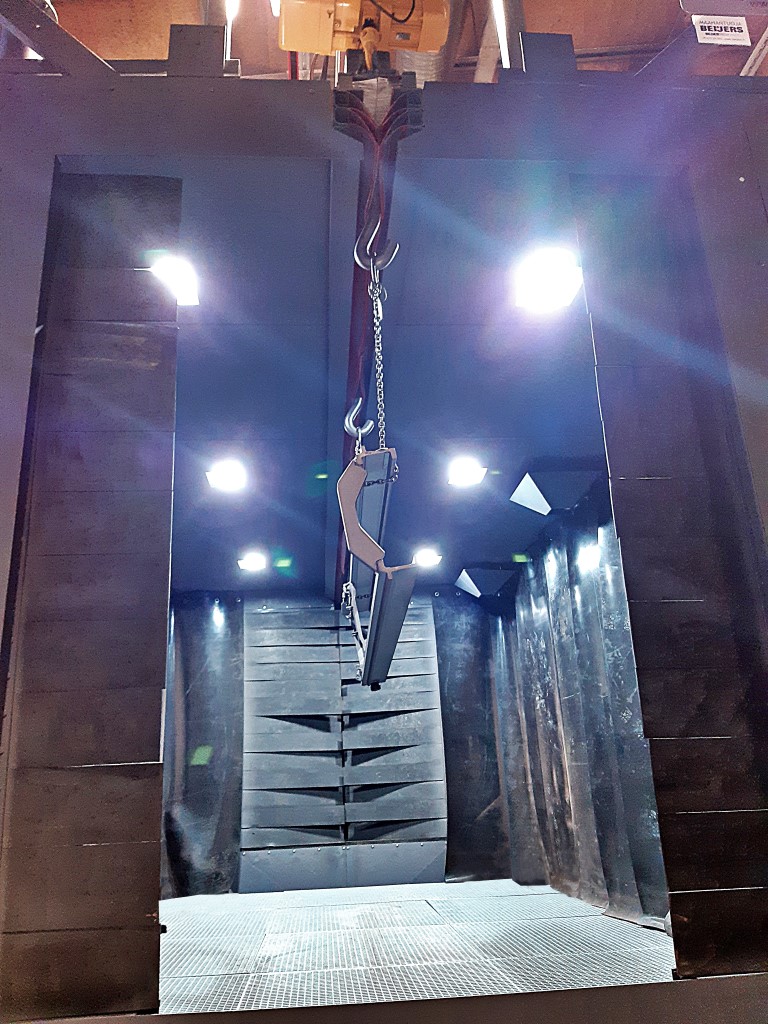

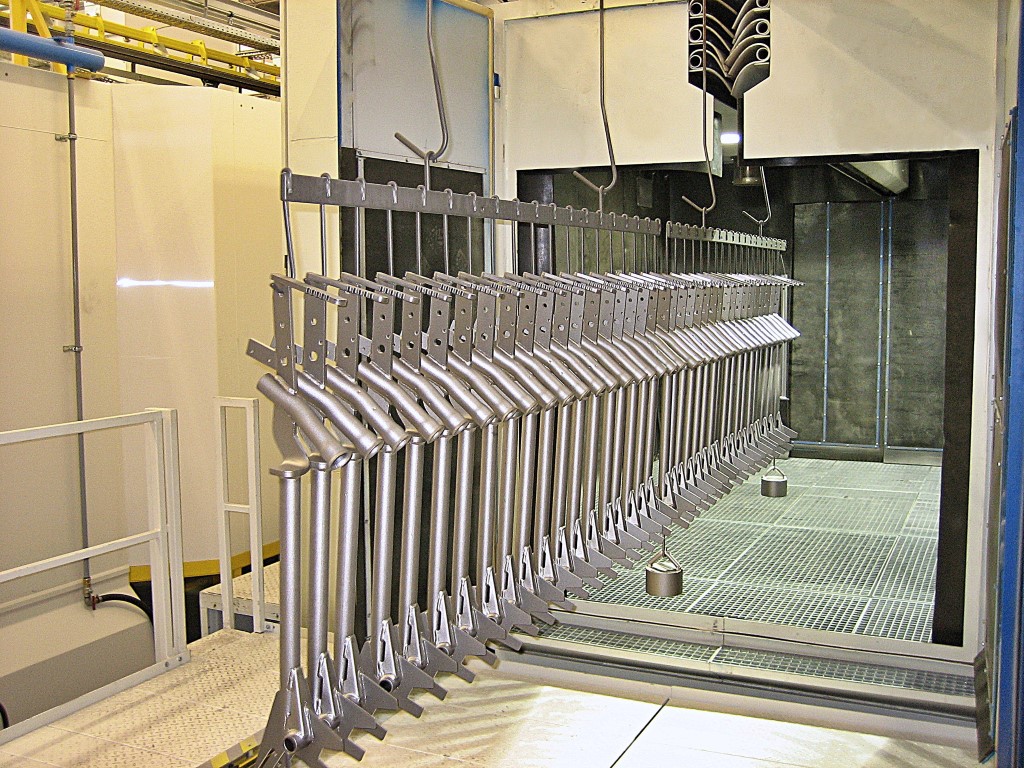

The workpieces are hung individually or in a cluster on hooks on an overhead conveyor, that goes through the shot blasting machine. Depending on customer’s requirements, a manually operated monorail or automatic power and free conveyor can be chosen.

During shotblasting, the workpieces move through jets of abrasive. The blasting wheels are installed at different angles depending on the direction of the movement which provides efficient treatment.

The housing of shot blasting machine is protected by wear-resistant manganese steel. The system for continuous return and cleaning of the abrasive together with efficient blasting wheels made of wear-resistant materials enable high efficiency of the shot blasting machine. Series of rubber screens keep the abrasive inside the shot blasting machine in entry chamber and exit cleaning chamber. It is also possible to install a manual chamber at the exit of the machine, which enables additional cleaning of the workpieces.

Pass-through monorail shot blasting machines may be built into highly productive lines for basic colour application, including drying chamber, automatic colouring chamber and drying tunnel.