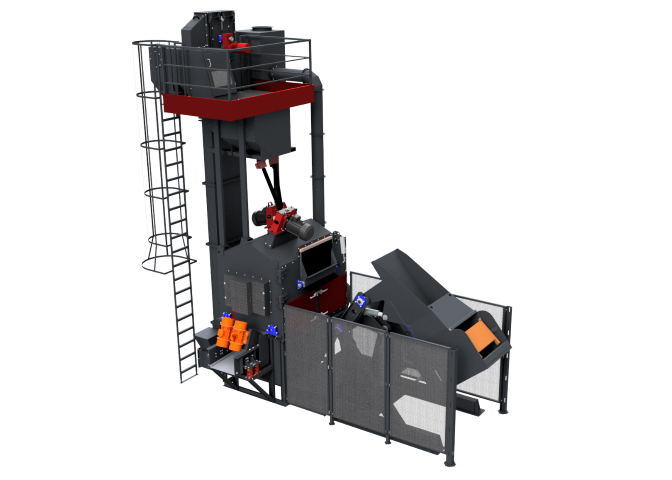

Rocker barrel shot blasting machine is ideal for shotblasting workpieces that are produced in large series and can be mass processed. It is ideal for smaller and lighter workpieces.

Workpieces are loaded into the shot blasting machine using a hydraulic loading device. On the ceiling of the machine are installed two blasting wheels, which enable fast and efficient shotblasting. During the shot blasting cycle the drum moves (with a twist) left and right, thereby causing the rolling of the workpieces in the drum. The cleaning – shotblasting – of the workpieces is double, from rolling and from the impact of abrasive.

After the shot blasting cycle is completed, the drum is turned 180° (upside down) and the workpieces fall onto the vibratory conveyor and are transported to the next operation.

The inside of the drum is protected by wear-resistant plates. High efficiency of the rocker barrel shot blasting machine is enabled by the continuous abrasive handling and reclamations system for continued returning and cleaning of blasting media, along with efficient blasting wheels made from wear-resistant materials.