During the creation and design of the Sm@rt cloud platform, our team remained committed to the goal of enhancing the operational efficiency of shot blasting machines and consolidating all data into a single, transparent location. Above all, we aimed to maximize the benefits for users. Our primary focus revolves around three key areas in which we aim to assist you:

- Reducing abrasive consumption

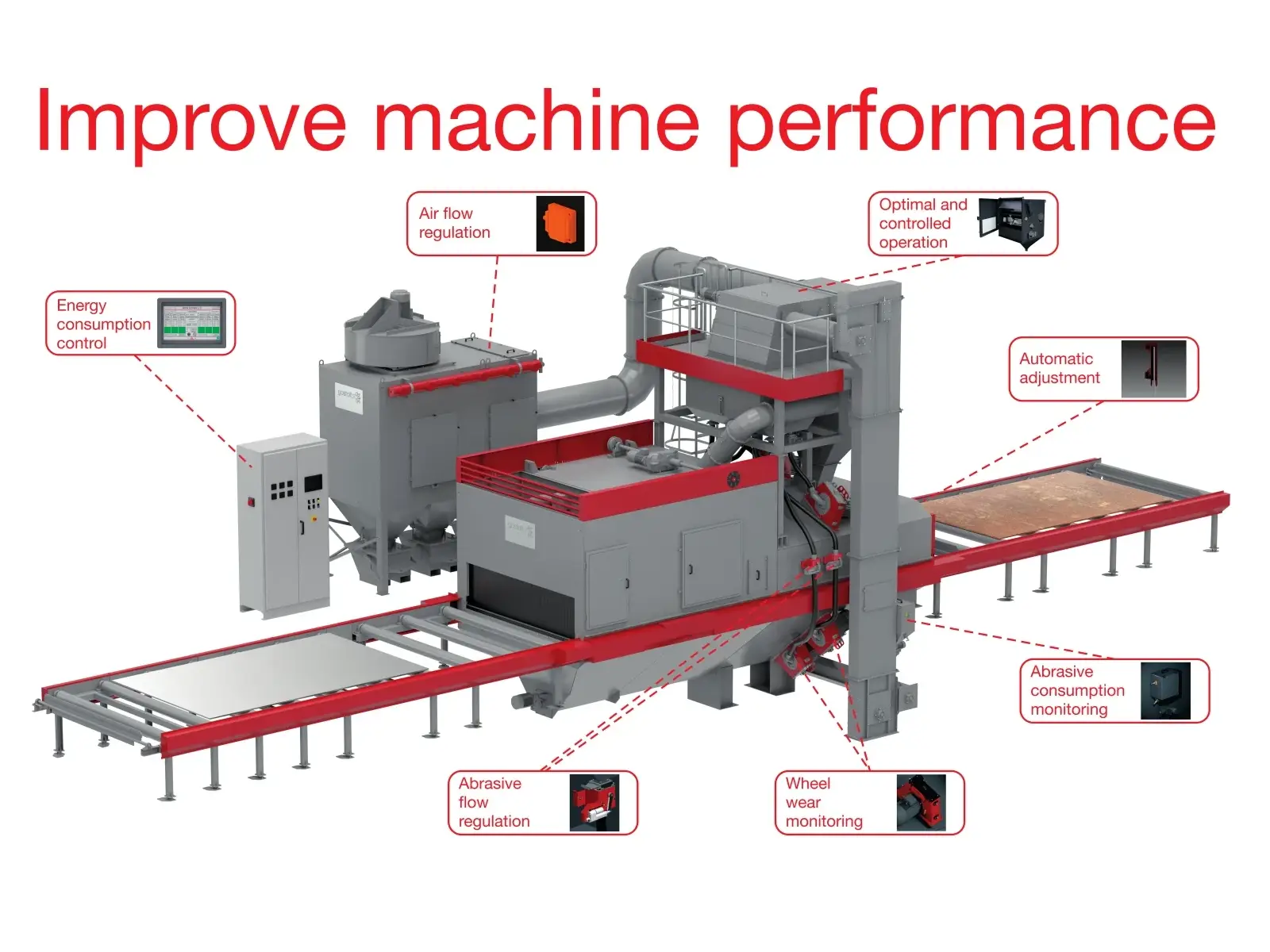

Abrasive (shot blasting media) consumption is a direct cost, influenced by the number of cycles and the energy transmitted by the blasting media. It is generally estimated that blasting media represent approximately 30% of the total blasting expenses. Optimal abrasive selection coupled with appropriate machine options, in tandem with the Sm@rt cloud platform, can lead to substantial cost savings.

- Achieving Energy savings

Electricity consumption is proportional to the blasting time and represents somewhere between 20% and 25% of the total costs. Key components influencing energy use in a shot blasting machine include blasting wheels, blasting media handling and recirculation systems, dedusting systems, and workpiece manipulation devices. By choosing certain machine options, significant energy savings are possible.

- Minimizing maintenance and production interruptions

A seamless production process with minimal unplanned interruptions is paramount. By monitoring specific parameters visible on the Sm@rt cloud platform, you gain a realistic overview of machine operations and receive timely notifications regarding machine wear or malfunctions. This empowers you to proactively maintain the shot blasting machine at optimal levels, thereby preventing unforeseen production halts and the accumulation of excessive spare parts inventory.

Drawing from your production process, our experts will provide guidance on the most sensible goal to pursue and recommend suitable options within that scope.