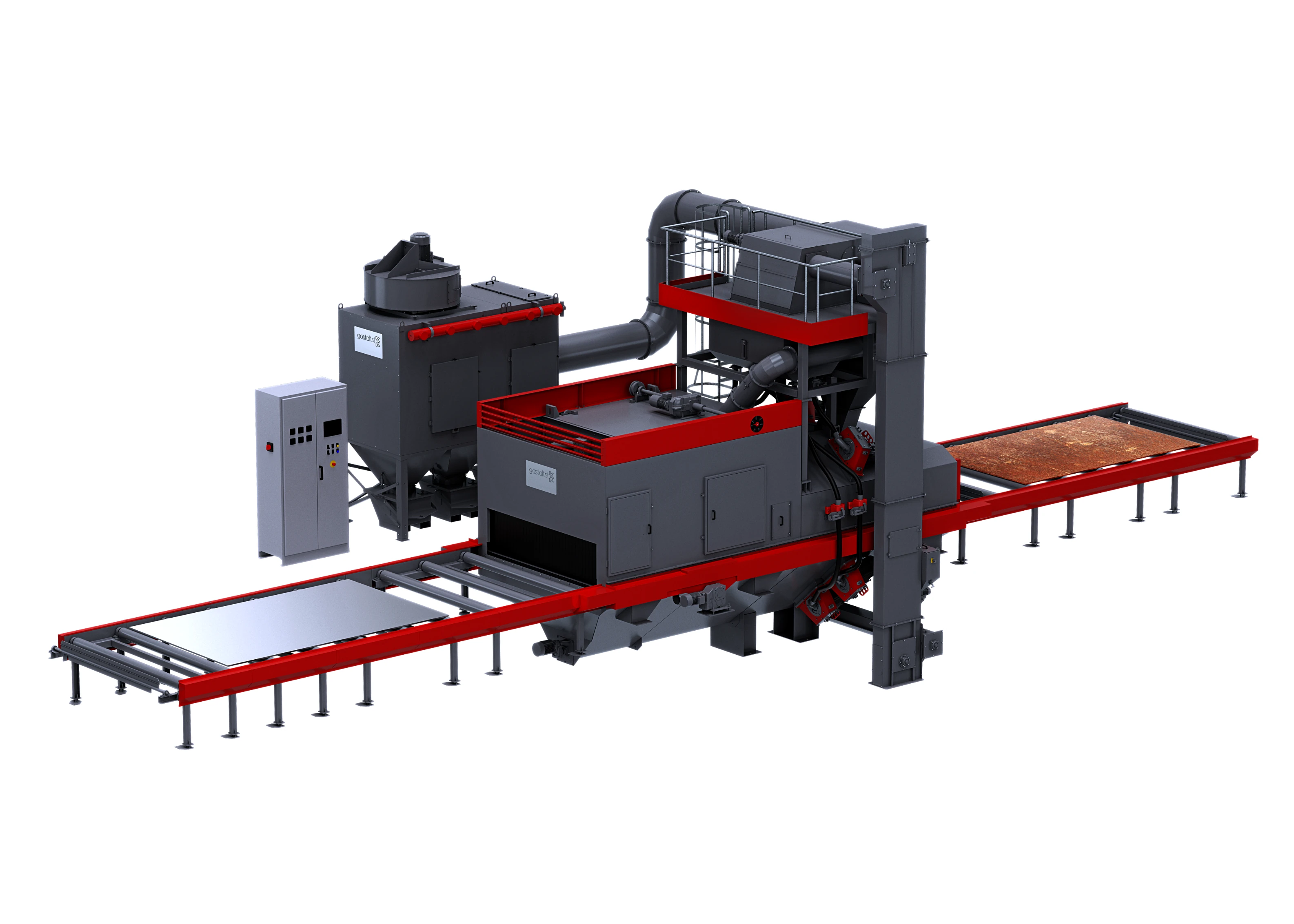

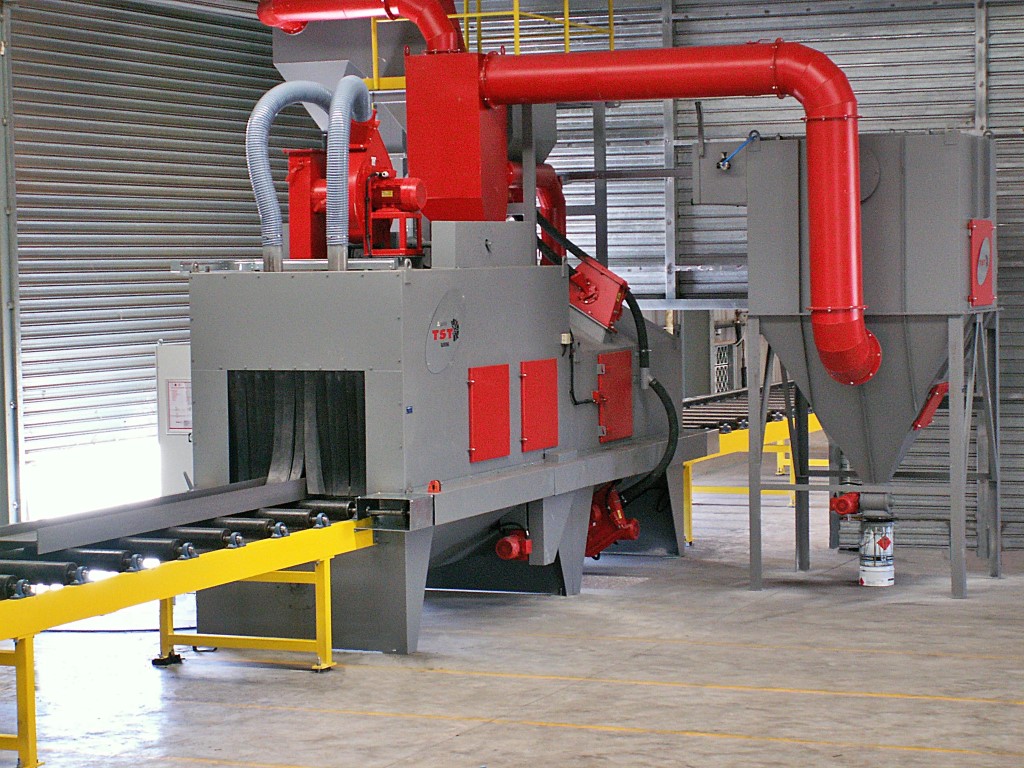

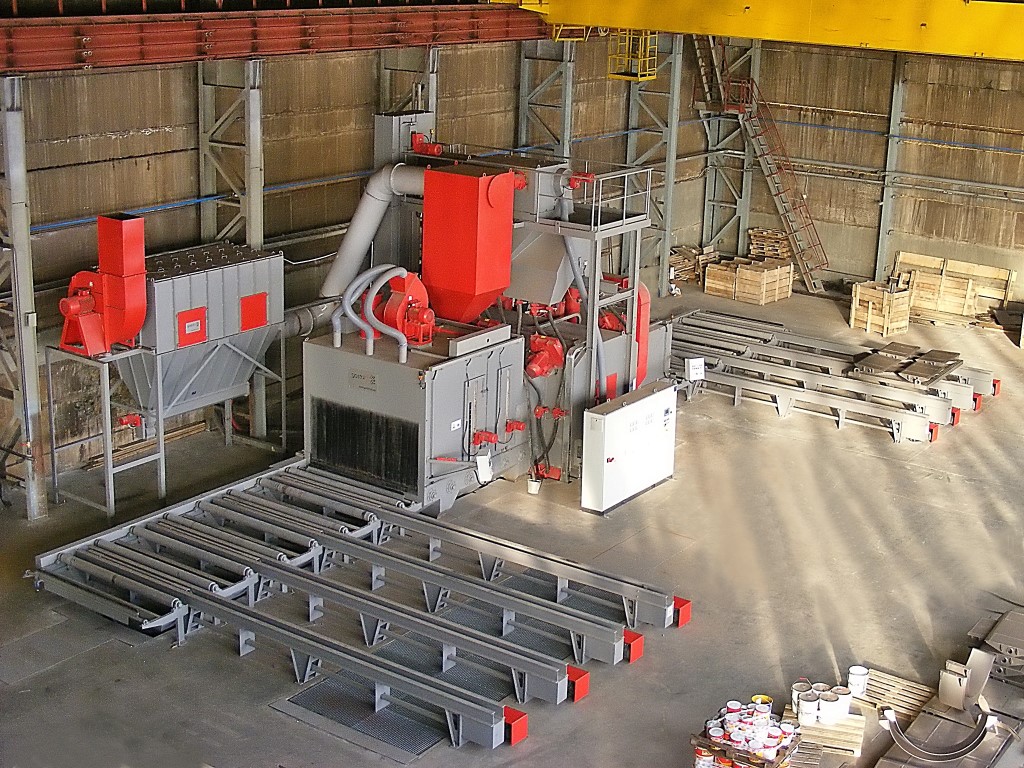

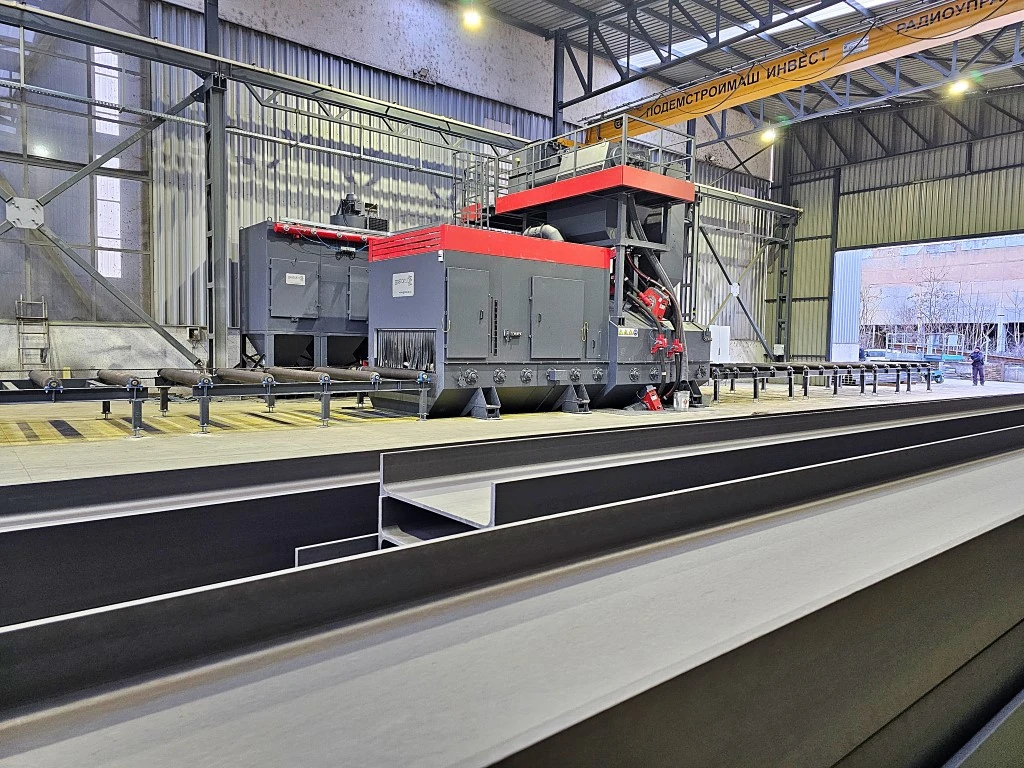

Roller conveyor shot blasting machine is primarily designed for shotblasting workpieces of larger dimensions, like steel sheets, profiles, beams and simple constructions. It is also possible to shotblast workpieces of shorter dimensions, which are loaded onto specially prepared housings or frames with mesh.

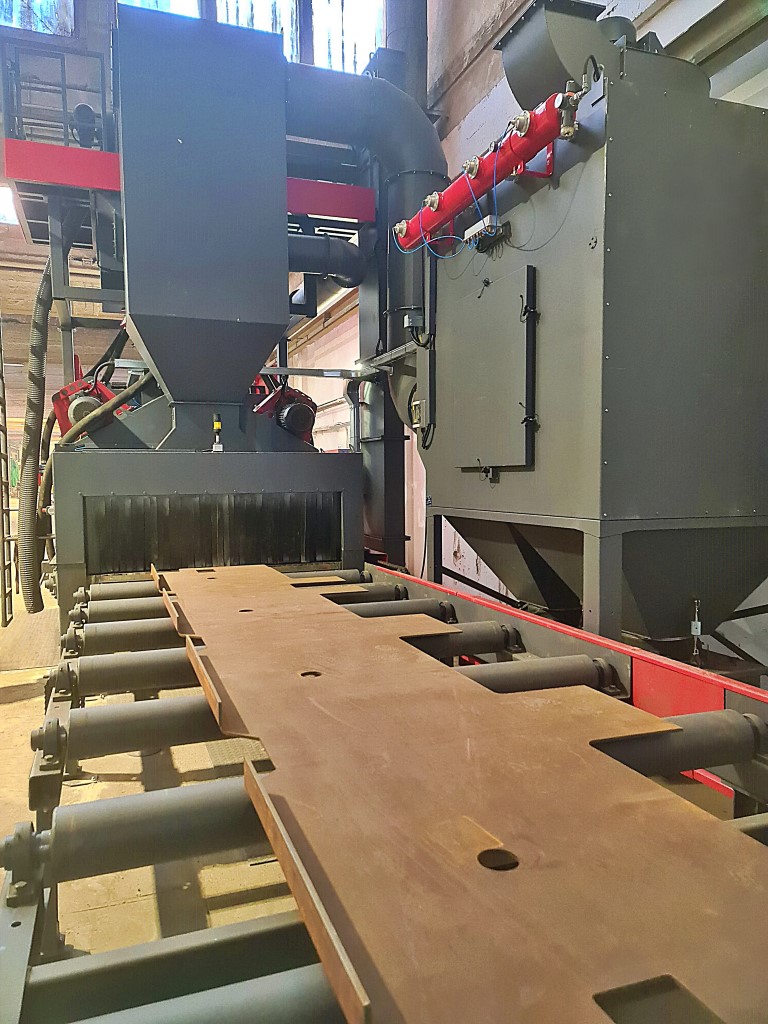

The workpieces are loaded onto a roller conveyor by means of a crane or forklift and transported through the machine. Depending on the process and the type of workpieces, the power of blasting wheels and the speed of roller conveyor are determined. All Gostol TST shot blasting machines have installed high efficiency ir blasting wheels. They are installed under a certain angle and have optimal positioning for less energy and abrasive consumption.

Roller conveyor shot blasting machine robust housing is protected with manganese steel shields, which are easy to replace and extend lifetime of machine. Series of rubber screens in entry chamber and exit cleaning chamber keep the abrasive inside the shot blasting machine. If any abrasive remains on the workpieces after the shot blasting process is completed, it is removed to a trough with quick height adjustable rotating brush and high-pressure fan. Screw conveyors, elevator and abrasive cleaner provide returning and continuous automatic cleaning of the abrasive.

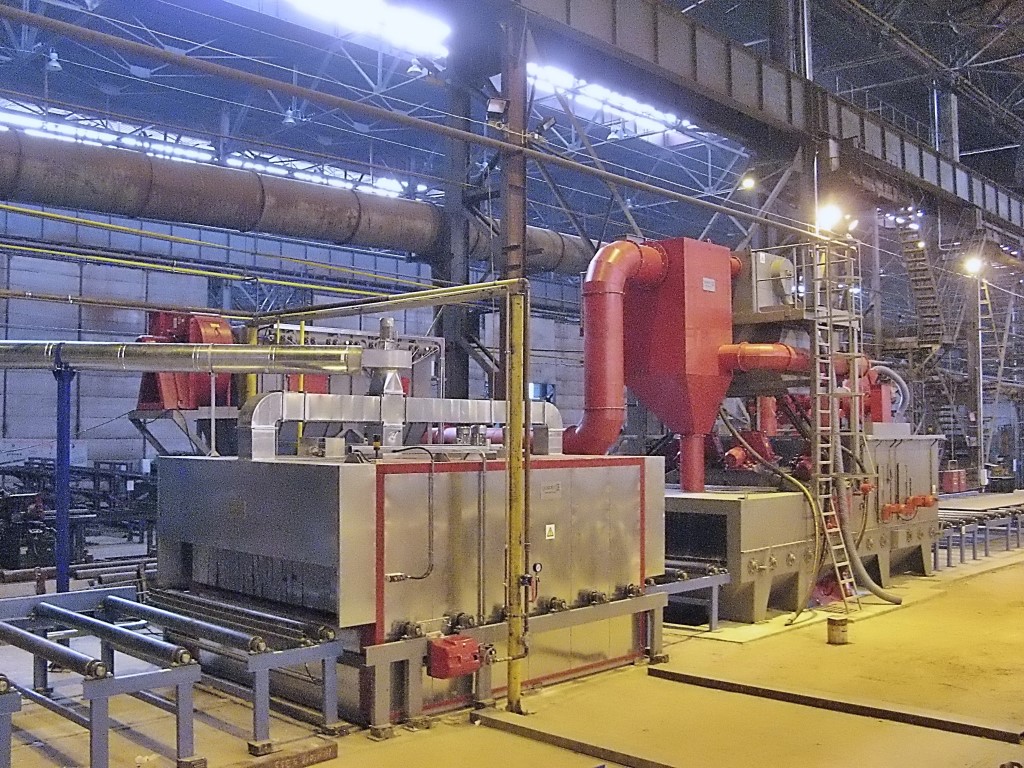

Roller conveyor shot blasting machines may be built into highly productive lines for basic colour application, including drying chamber, automatic colouring chamber and drying tunnel.

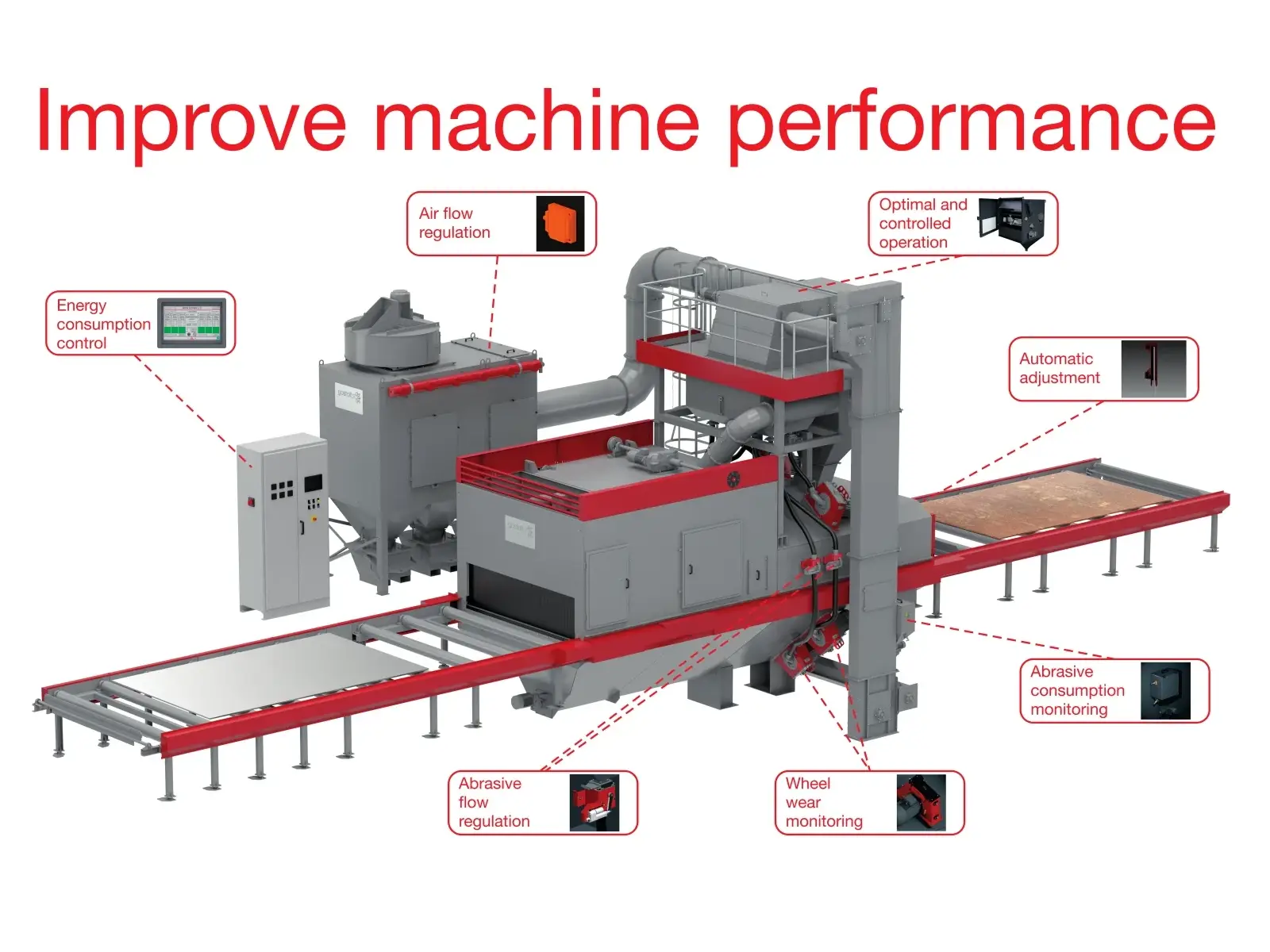

The machine can be equipped with additional options that increase efficiency, reliability, and operational transparency.

With the connection to the sm@rt cloud platform, real-time monitoring and analysis of key operating parameters are enabled, contributing to optimized maintenance, longer component lifetime, and reduced operating costs.

Upgrade and design options

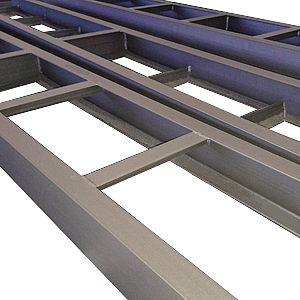

The roller conveyor shot blasting machine can be designed in various configurations, adapted to the types of workpieces, productions process, and the customer's space requirements.

Available versions:

- Standard version - intended for blasting plates, profiles, and simple steel structures.

- Version with cross conveyors - enables automatic loading and unloading of workpieces.

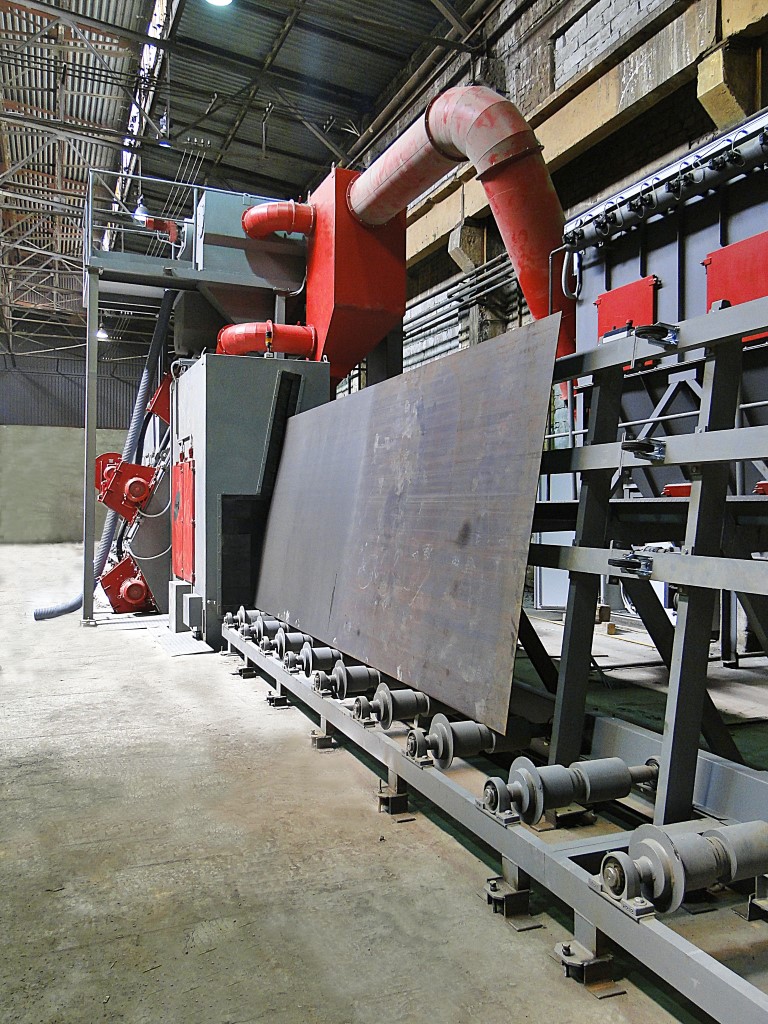

- Version with the sheet transport manipulator type VP - allows fast, safe, and ergonomic handling of plates, reduces physical strain on operators, and increases line productivity.

- Special customized versions - including a vertical designof the P machine for blasting large plates and a layout with both loading and unloading on the same side, ideal for space-restricted installations.

Integration into painting lines

The roller conveyor shot blasting machine can be integrated into high-capacity primer painting lines, including a drying chamber, automatic painting booth, and drying tunnel. This integration enables a fully automated process of surface preparation and protection.

System flexibility

Each version of the roller conveyor shot blasting machine is designed to allow upgrades with additional options or automated transport systems, ensuring optimal adaptation to existing production and a higher level of automation.